Please view our 5* google testimonials

Welcome to active southwest

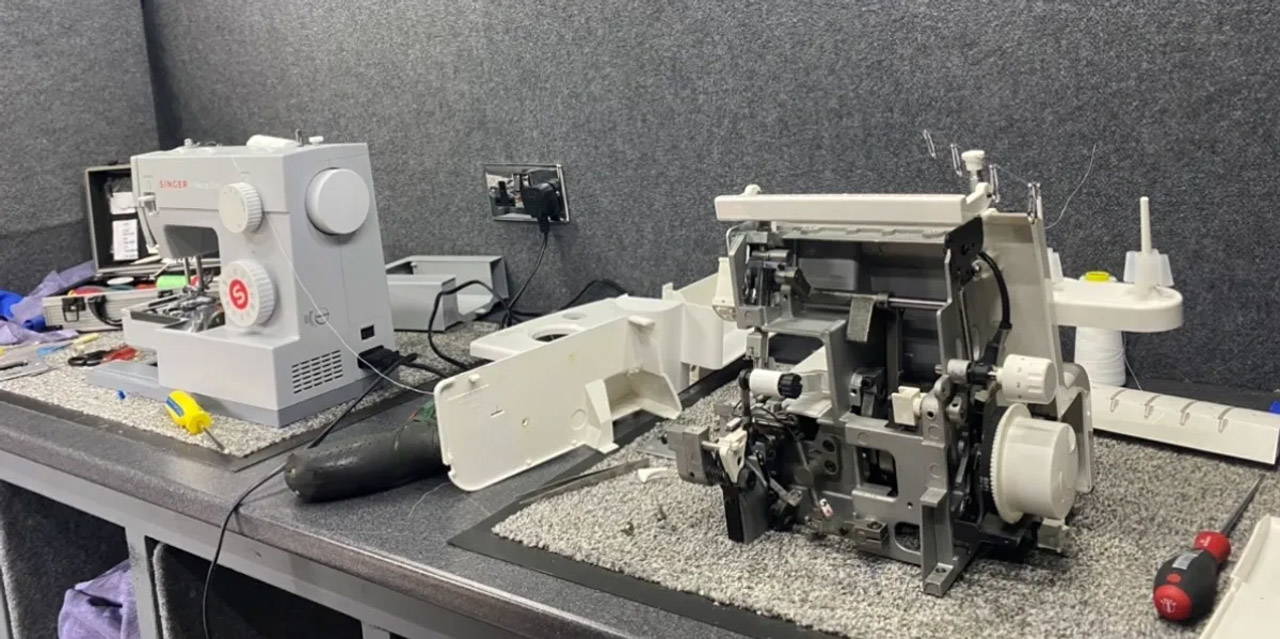

Specialists in Sewing Machine Repairs & Servicing

Active Southwest is your local expert in all aspects of sewing machine repair and maintenance. We’re an independent business with years of experience, offering reliable and professional service across most of the South West.

About us

We can take care of any repair and cover all your servicing needs. Our technicians are ACTIVE across most of the SOUTHWEST.

Mobile workshop

We understand how important your sewing projects are. That’s why we offer on-site repairs, so you don’t have to pause your work or send your machine away unnecessarily.

Expertise

We are sewing machine repair and servicing specialists and have years of knowledge & experience.

Whether you’re a hobbyist or a professional, you can count on us for high-quality, efficient service tailored to your needs.

Machines

We repair and service all Domestic types and models of sewing machines – from classic vintage machines to the latest digital models. Whatever the issue, our skilled technicians are here to help.

ABOUT ACTIVE SOUTHWEST

Please see a map of the area we cover below.

Preventative Maintenance

Regular maintenance can extend the life of your sewing machine and prevent costly repairs down the line. We offer comprehensive preventative maintenance services to keep your machine running smoothly.

1. Inspection

Visual Check: Inspect the machine for any visible signs of wear or damage.

Functionality Check: Test the machine to ensure all functions (stitching, threading, etc.) are working correctly.

2. Cleaning

External Cleaning: Wipe down the exterior to remove dust and debris.

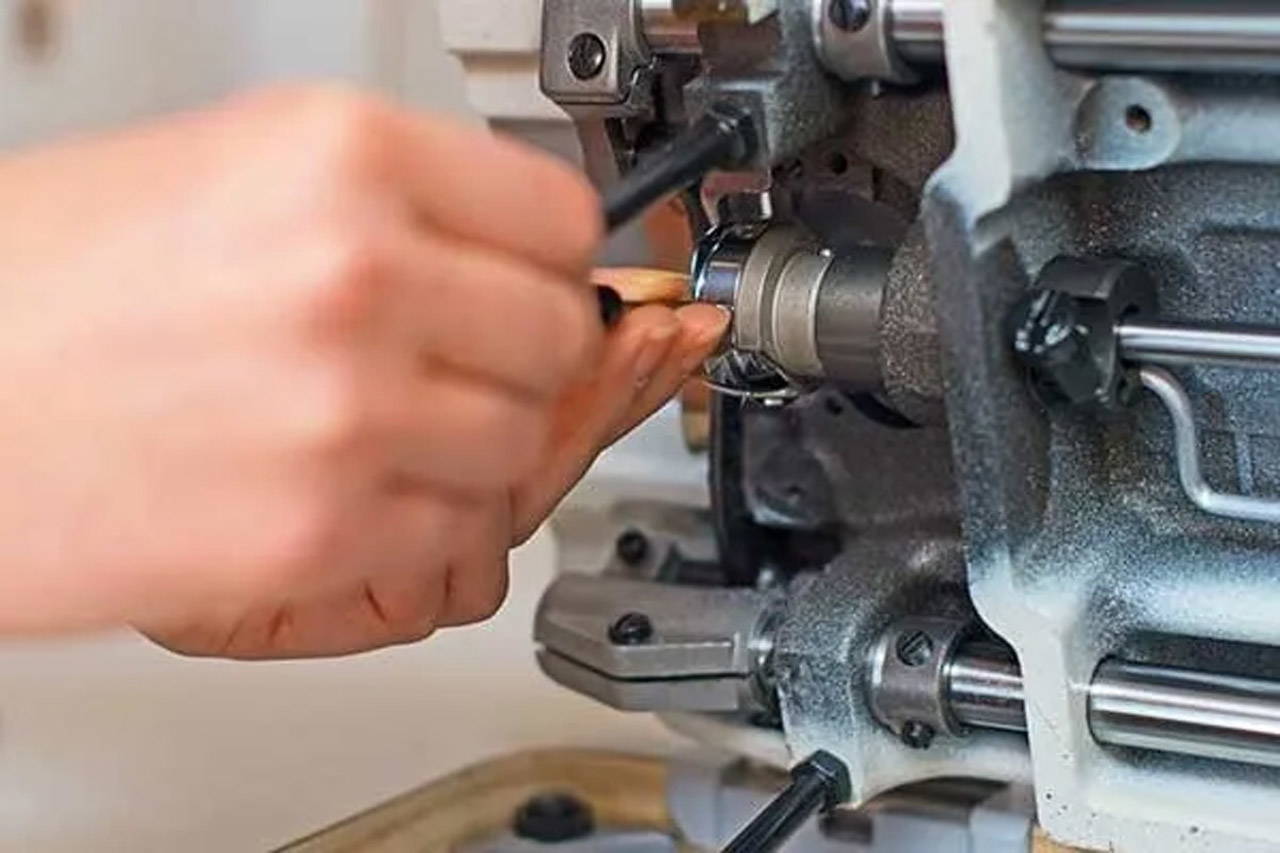

Internal Cleaning: Open the machine to clean internal components, including the feed dogs, bobbin case, and needle plate. This often involves using a brush and compressed air to remove lint and dust.

3. Lubrication

Oil Application: Apply sewing machine oil to moving parts to reduce friction and wear. Proper lubrication helps ensure smooth operation and reduces the risk of overheating and damage.

4. Tension Adjustment

Thread Tension: Check and adjust the upper and lower thread tension to ensure balanced stitching. Proper tension is crucial for consistent stitch quality.

5. Needle and Thread Path Inspection

Needle: Needle replaced. A damaged needle can cause stitching issues.

Thread Path: Ensure that the thread path is correctly aligned and not causing snags or irregularities in stitching.

6. Timing and Alignment

Timing Adjustment: Check and adjust the timing of the sewing machine to ensure the needle and feed dogs are properly synchronized. Proper timing is essential for accurate stitching.

Belt and Gear Alignment: Inspect and adjust belts and gears to ensure they are properly aligned and functioning correctly.

7. Bobbin Case and Feed Dogs

Bobbin Case Inspection: Clean and adjust the bobbin case to ensure it is functioning correctly.

Feed Dog Check: Inspect and adjust feed dogs to ensure they are moving the fabric correctly.

8. Electrical and Motor Check

Electrical Components: Test electrical components, including the foot pedal and wiring, to ensure there are no issues.

Motor Inspection: Check the motor and ensure it is operating smoothly without unusual noises or issues.

9. Final Test and Calibration

Stitch Test: Perform a test run with different stitch patterns to ensure everything is functioning correctly.

Calibration: Make any final adjustments to ensure that the machine is calibrated for optimal performance.

10. Recommendations and Follow-Up

Customer Advice: Provide recommendations for any additional repairs or parts that may need attention.

Maintenance Tips: Offer advice on how to care for the sewing machine between services to prolong its life.

Additional Services (if applicable)

Part Replacement: Replace worn or damaged parts, such as belts, gears, or other components.

Specialized Repairs: Perform repairs for specific issues, such as thread jams, needle breakage, or electronic malfunctions.

Regular servicing helps prevent minor issues from becoming major problems and ensures that the sewing machine continues to operate efficiently and effectively.

Customer-Focused Service

We pride ourselves on providing the highest level of customer service. Our team will work with you every step of the way to ensure your sewing machine is serviced to your satisfaction.

Contact Us

SEWING MACHINE REPAIRS

We respond to every email so please check your junk folders if you haven’t heard from us. Thank you.

Active Southwest

Telephone: 07817 526717

Email: activesouthwest@gmail.com

Hours

Monday – Friday: 09:00 – 17:00

Saturday – Sunday: Closed

Active Southwest

Copyright © 2025 Active Southwest – All Rights Reserved.